How it works

Seawing is a towed hydro-generator. It allows you to recharge your boat’s batteries while you sail. It is connected to your boat by a flexible cable ensuring both the mechanical holding function and the electricity transfer function.

It is made of a marine aluminum frame to which two counter-rotating propellers, a float and a stainless steel fin are attached. Sacrificial anodes are positioned on the propellers and on the fin to prevent corrosion problems. It weighs approximately 6 kg and its propellers have a diameter of 240 mm.

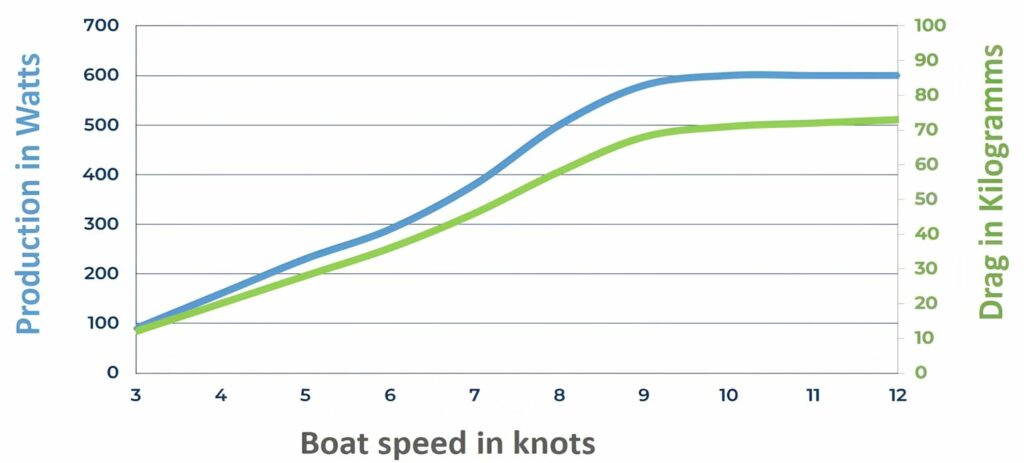

As soon as the boat speed exceeds 3 knots, the hydro-generator propellers start and charge the battery. The float coupled with the massive stainless steel fin allows the system to be positioned in the water. The 12° inclined fin allows the system to be maintained at an optimal depth over the entire operating speed range of the hydrogenerator.

Performance depends on several factors. Generally speaking, the faster the boat, the bigger the production. Another important parameter when it comes to performance is the installation height. The lower the fixation point, the deeper in water seawing will be. As cavitation decrased with depth, the production will be better.

Seawing is software limited to 600 Watts power production. If that maximum is reached, the hydrogenerator will decrease it ‘s production automatically. Curves given below are for 240mm diameter propeller. Those propeller are best suited for low speed boat with a mean speed between 5 to 6 knots. For faster boat , we recommend using our 210 mm high speed propeller.

Easy Installation Process

The hydrogenerator comes with a stainless steel carabiner to attach the system to an existing attachment point on your boat. We recommend to have the attachment point as low above sea level as possible. However, the system can work with an attachment point up to 1 meter above sea level.

You have to install seawing connector on your boat transom sot that there is no mechanical stress on the electrical connector. Six cables must be installed between the electronic box and the electric connector. To help in the installation process, we can provide you with prewired connector. We also numbered the wires so that any mistakes are avoided.

On battery side, you can connect the electrical box directly to the battery but we recommend to install an aditionnal resetable fuse ( 100A) for security. We can also provide battery cable with specific length and lugs ( diameter 6/8 or 10mm). The electronic box can also be installed after a battery controller (connect the minus behind the current shunt).

Robust Design

Seawing main frame is made of marin aluminum. All screw and bolts are stainless steel. Polyamiade washers prevent galvanic corrosion between stainless steel and aluminum. Seawing cable is made of 6 silicon wires with of 2.5mm² section. Silicon is not affected by sea water. Cables are covered with a dyneema braid ensuring recovery of the drag forces of the hydro-generator. Thus the electrical cable is not subject to any mechanical stress.

Motors are fully potted (winding and magnets) with polyurethan resin and silicon. An additionnal ceramic bearing is added to the back of the motor to counteract propellers pull. Inner motor bearings are not subject to that force. A custom stainless steel shaft for that purpose is mounted on the motor in factory.

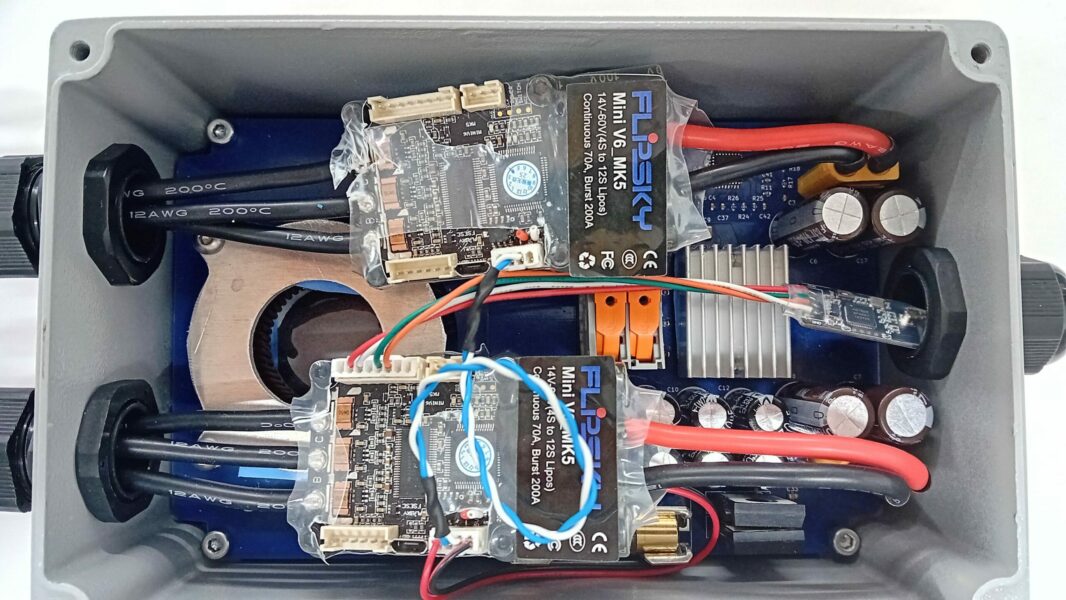

High Efficiency controller

– Dimensions: 160x80x56mm.

Seawing controller is made of two independant motor controllers, one master and one slave. Both motors perform regenerative braking to generate electricity and charge your batteries. Electrical production is maximised with an electric conversion efficiency above 95%.

– MPPT algorithmThe inboard software follows the torque vs rotationnal performance curves of the propeller in real time. Whatever your boat speed, production is always maximise.

– Autopower ON/OFF A soon as the propeller rotate, the electronic box power up. After a 30 min rest delay, the electronic box automatically switch off if it detects no rotation.

Battery Voltage detection It automatically adapt it’s settting to your battery voltage (either 12 or 24Volts). Rest current of the electronic box when off is around 600 micro-Ampères, insuring that your battery stay charged even after months without using it.

– Full charge battery detection When your battery is almost full, the production of the hydrogenerator slowly decreased up to the point where your battery is full and the production is stopped.

– Overcurrent protection The electronic include a 80 Ampères fuse to protect your installation from shorts circuits or wiring error. Our electronic also include a fast current sensing feature to prevents the electronic from short circuit conditions and protect itself. On the front face you can find the power ON/ power OFF button and the brake button. Power On button will light up green when activated. brake button must be used to stop the propellers and retrieve the hydrogenerator.

Mobile phone application

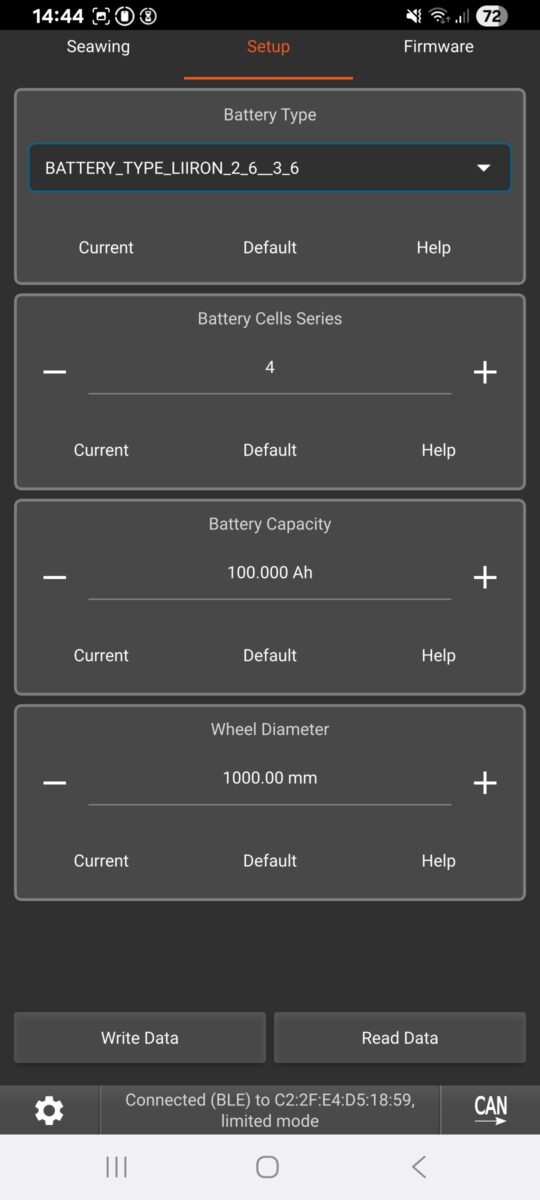

Seawing comes with its on mobile phone application. You can connect to the electronic using a strong bluetooth low energy signal from anywhere on the boat. Once connected, four tabs are available:

–Real time tab: you can check seawing production data such as propeller speed in RPM, battery current in Amperes, hydrogenerator power in Watts and your Battery voltage in Volts

–Parameters tab: you can tune your hydrogenerator to your elctrical installation: select the correct battery chemistry( lead-acid / li-ion / LifePo4), battery voltage ( 12 or 24VDC). You can also configure the cable legnth between electronic box and batteries to make sure the battery voltage calculation used for full charge battery detection is accurate.

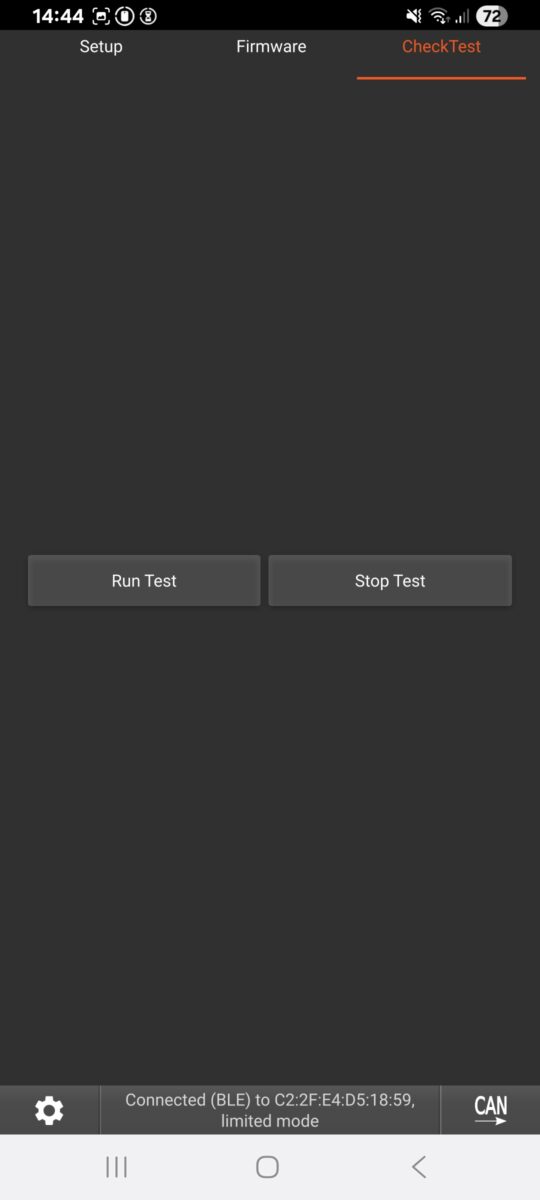

–Checktest tab: allows you to check your electrical connections when you finished installation. Just press a button and see if motors are working fine in a minute.

–Firmware update tab: when a firmware update is available, we will send it to you. Just select the file we send you and click on update to have latest Seawing firmware available.